STAMPED CONCRETE WITHOUT CONCRETE

With a special formulation containing advanced dry-form polymers and specialized admixtures, TopCrete 601 is applied in small thicknesses, 10 mm on average, rendering the process of producing a stamped concrete finish a breeze. Thanks to its thin-set nature, material accessibility and logistical challenges are no longer a barrier to enjoying the benefits of stamped concrete finish anywhere.

TINY BUT MIGHTY

Despite its small applied thickness, TopCrete 601 is extremely durable and tough, with an abrasion resistance greater than that of regular concrete and a compressive strength of 20MPa in just seven days.

STAMPED CONCRETE FINISH MADE EASY

No cumbersome formwork or messy concreting, just set a simple shutter, mixwith water, and plaster onto the prepared substrate, then apply release agent and stamp. That’s it!

And with its shrinkage compensated formulation, TopCrete 601 does not require the construction of control joints, allowing for an attractive and natural-looking seamless installation on interior spaces.

Advantages

Thin application: featheredge to 25 mm.

Shrinkage free, enabling seamless interior applications.

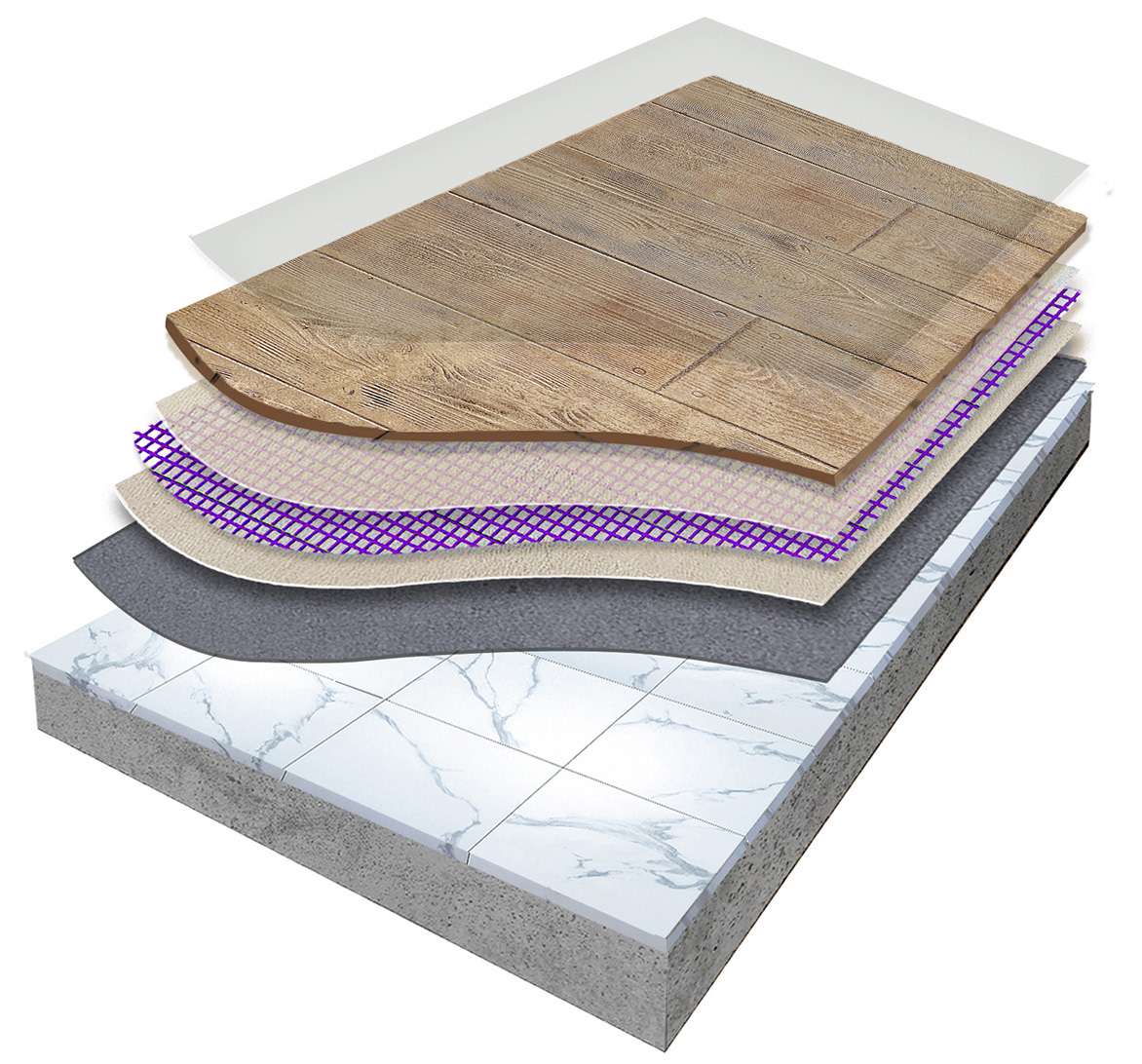

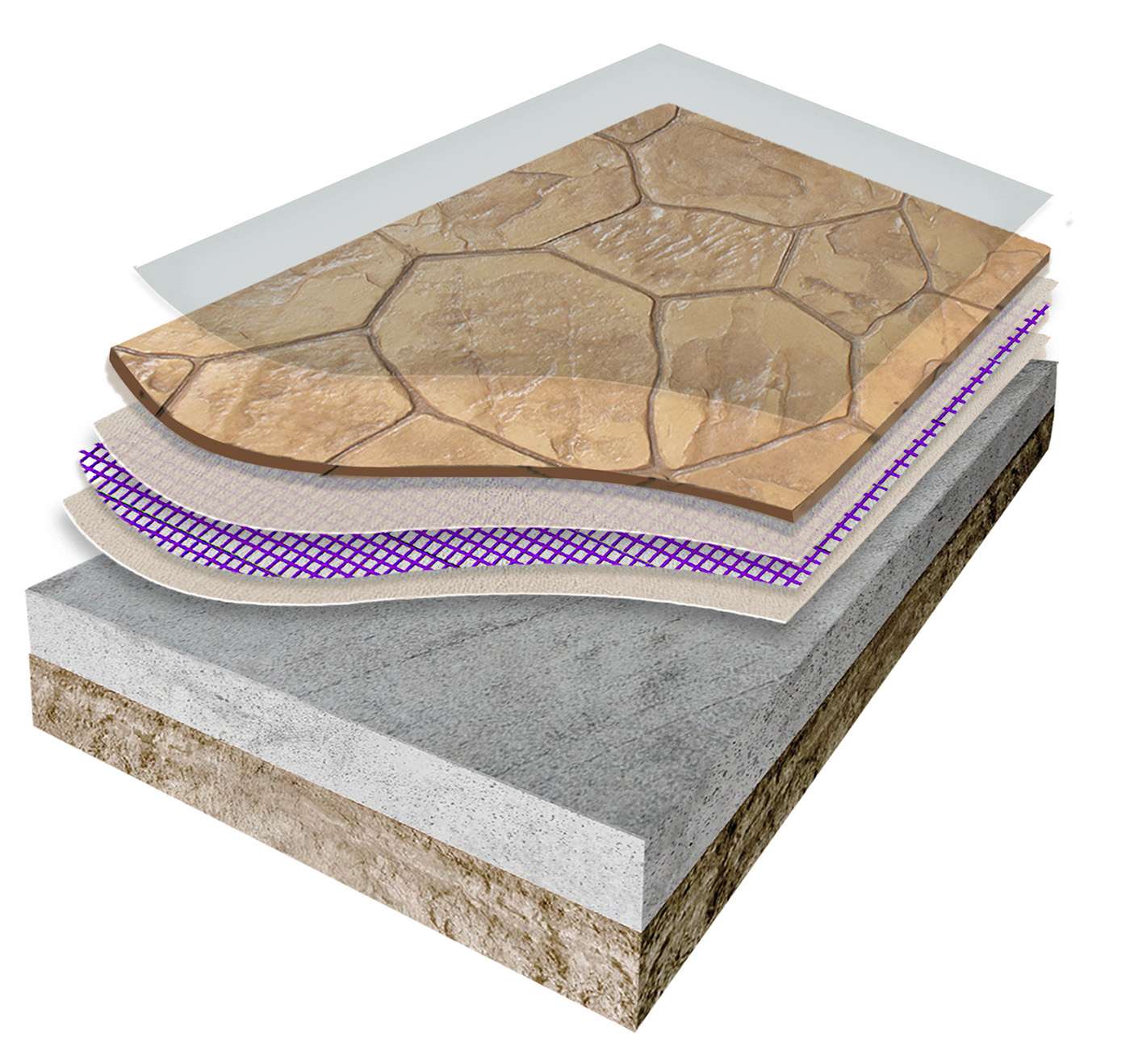

Ideal for renovation projects, no need to remove the existing surface.

Higher abrasion resistance than conventional concrete.

Easier and faster to execute than stamped concrete.

Higher abrasion resistance than conventional concrete.

Single component; just add water.

40+ standard colors.

Interior / exterior.

Walls / floors installations.

Self-curing.

Walls / floors installations.

How It's Done

System Details

Concrete Substrate

CCC Premium Mesh (Optional)

Sealer Coat (A-Z Mega Sealer, A-Z Ultra Sealer, ElastoCrete 200)